For a future project, I want to use gears that work at a right angle and I want to make them with a laser cutter. Gears that are mounted on parallel shafts are easy to make with a laser cutter. For gears meeting at a 90-degree angle bevel gears are the standard today. The disadvantage of bevel gears is that they are quite difficult to design and make because they have a conical surface.

An alternative to bevel gears would be to use cage and peg gears. They have been used in windmills for hundreds of years. Their construction is fairly straight forward and they can be made by gluing dowels into the laser cut wood.

The main disadvantage of this type of gear is that they require considerable time to assemble.

Simple laser cut right angle gears

I want to test if a simpler solution would also work for my requirements. The simple solution is to use normal spur gears and just mount them at a right angle.

Of course, this solution won’t be as mechanically efficient as true bevel gears. My gears won’t run at high speed and won’t have to transmit a lot of torque so I hope to be okay with the simpler version.

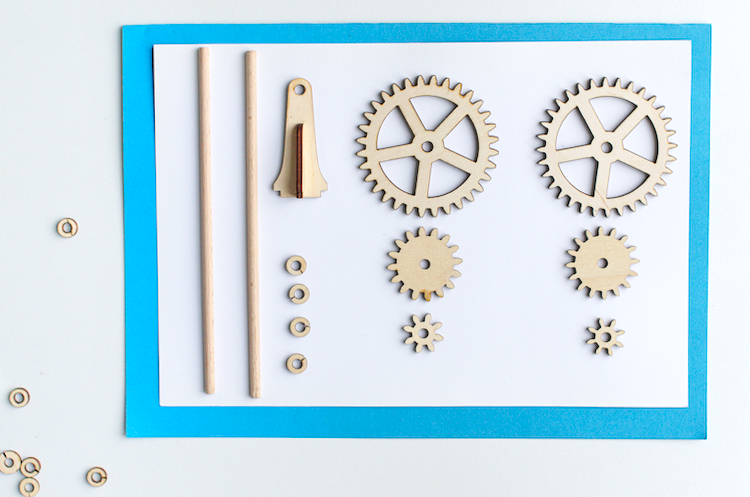

I used the Fusion360 spur gear add-in to create three different gears for my test. A large on with 32 teeth a middle one with 16 teeth and a small one with 8 teeth. I also designed a little test stand for my gears.

Here you can see the cut parts. I made two versions of the gear sets. For one I used the gear profile created in Fusion360 and for the second set of gears, I create a new profile by offsetting the original line by 0.5 millimeter.

Testing the gears

My plan was to fix the gears on the wooden dowel shafts by using press fitted spacers. Unfortunately, I made a beginner mistake by not checking the exact diameter of the shafts.

I bought them labeled with a 6 mm diameter but actually, the diameter is mostly about 5.8 mm. This might not seem like a big difference but it is enough to make my spacers not fit tightly anymore.

I was able to do some first tests and the results look promising – the gears turn! Yet I could not do any detailed test because after a few turns the spacers start to move and the gears get out of alignment. I plan to get some 6 mm threaded screws as replacement of the wooden shafts and use nuts to mount the gears.

Update: I tested the gears mounted with nuts and bolts.

This is an interesting project. Thanks for your inspiration. I added it to my ‘to do list’.

Kind regards,

Angela

Thanks! Happy I could “spark” some inspiration 🙂

Nice one. I will try in my gear venture next…